Oak plywood is made using veneer for the outer layers. Plywood is constructed by layering thin sheets of wood plywood or veneers at right angles to each other, and then they are bonded together with adhesive under heat and pressure.

Oak plywood specifically uses oak veneer for one or both of the outer layers, providing the appearance of oak wood while retaining the structural benefits of plywood

Breaking It Down:

Cores

The front layers of large sheets of plywood are the “core” of the board. They affect properties on the edges of the panel, like weights, price, screw-holding ability, water resistance, and stability. The plywood veneer face is generally of higher quality or “grades” than its main material.

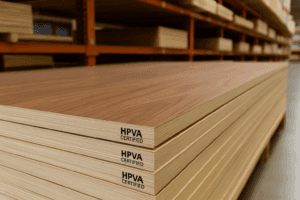

The surface of a veneer varies based on its appearance. The decorative hardwood industry association (DHA) (formerly the Hardwood plywood and veneer associations) can determine plywood grades.

Face Types

AAA Grade face. High-end veneer for all types of veneer. It is a smooth, straight cut and long with no visible imperfections or abnormalities. A-Grade faces: An A-face on plywood is required to match the grain and the color.

Almost all veneers must match for an appealing appearance. There should not be any abrupt change in colors between the splices.

Faces can not tolerate rough or cracked veneers or broken knots. A face with thin veneers can have a mineral or vine mark. The number of thin veneer defects, including pin knots and small burls, differ depending on the veneer type.

Grades

As with other hardwood plywood, oak plywood is graded in two different ways: first, it is graded for the quality of the veneer finish, and second, it is graded for the type of core. Oak plywood is considered “good” on both veneered edge sides, although one side is distinctly the face side, leaving the other as the backside. The face side is graded from “A” to “D, with A being the finest quality.

The back side is graded with numbers, from “1” to “4.” For cabinetry and furniture, grade “A2” is the most commonly used, although grades B and C are often used for internal shelving and cabinet backs. The chart on the page about cabinet-grade plywood presents more about visible and back-face grades. Lower grades are considered paint grades.

The face veneer on oak plywood sheets can vary greatly in thickness, depending on the manufacturer and their commitment to quality. While most veneers used in plywood are rotary cut, veneers used on quality oak plywood and other hardwood plywood are plain sliced, giving the appearance of oak boards laminated and glued together. The highest grades of oak plywood have bookmatched veneers on the face, but they also have the highest prices.

Layers

The biggest difference between the various grades of oak plywood is the core. While softwood plywood always has some layers of back veneer, which are laid 90 degrees to each other, hardwood plywood can have any material between the face and back veneers.

Therefore, oak plywood can be veneer-cored concrete, like softwood plywood, or a “solid core” particleboard or MDF (Medium Density Fiberboard). While the veneer core of real wood is structurally stronger, particleboard and MDF provide a more stable, flatter sheet with a more consistent thickness.

The loss of structural strength in particleboard and MDF core oak plywood construction is essentially caused by the lower screw pullout strength inherent in these materials. However, in most cases where oak plywood is used, the panels are edged with solid oak hardwood, ensuring sufficient strength for mounting hardware and connecting panels.

The problem with veneer core oak plywood is that any imperfections in a core layer will affect the adjacent layers. If the imperfection is large, multiple layers thick, or close enough to the face veneer, it will show in the cabinet’s finish. Unfortunately, this normally doesn’t show up until after finishing.

Which is better, oak or maple plywood?

Maple is a strong and durable wood found in almost any kitchen. Both are hardwoods. Despite this, maples are slightly harder to handle than oaks. Maple is a durable and strong wood choice for any home.

Where to use oak plywood

Oak has long been a favorite hardwood for millwork, furniture, and cabinet-making. It is also often used in interior paneling and many other woodworking projects.

Design Trends

Oak wood has many advantages for its durable and aesthetic properties. Since the 1800s, it has helped our home create a comfortable, warm atmosphere that doesn’t go out the window. It stands out for this reason. Red and White oak veneers and plywood can be found at most retailers, and Red oak has a lower price point.

White oak plywood

It can serve many useful purposes, and the best application will depend on the usage case. Not only is it warm and sophisticated for the retail and residential sectors, but the product also delivers an appealing, homey feeling. Moreover, white oak wood is ideal for decorating walls or ceilings for a peaceful ambiance you and your family will surely enjoy.

Why Choose Oak Plywood

Oak is well known for its density and hardness. It has high strength and beautiful grain contrast and patterns. Solid wood edging provides the same beauty as solid boards or maple while reducing material cost, guaranteeing panel flatness, and making it easier to work.

The product is powerful and versatile. In a closet, it’s best to buy oak plywood. It is a highly reliable option because of its variety of colors. It has incredibly good wear resistance, and this helps maintain a long-lasting value.