Skirting is an essential feature for mobile homes, offering protection, insulation, and a polished appearance. Skirting is a valuable investment whether you’re looking for an affordable way to enhance your home’s curb appeal or need additional insulation. Here’s a step-by-step guide on how to install skirting on your mobile home.

Materials Needed:

✅ Treated lumber or galvanized metal framing

✅ Screws or nails

✅ Drill or hammer

✅ Circular saw or hand saw

✅ Measuring tape

✅ Level

✅ Insulation (optional)

✅ Paint or sealant (optional)

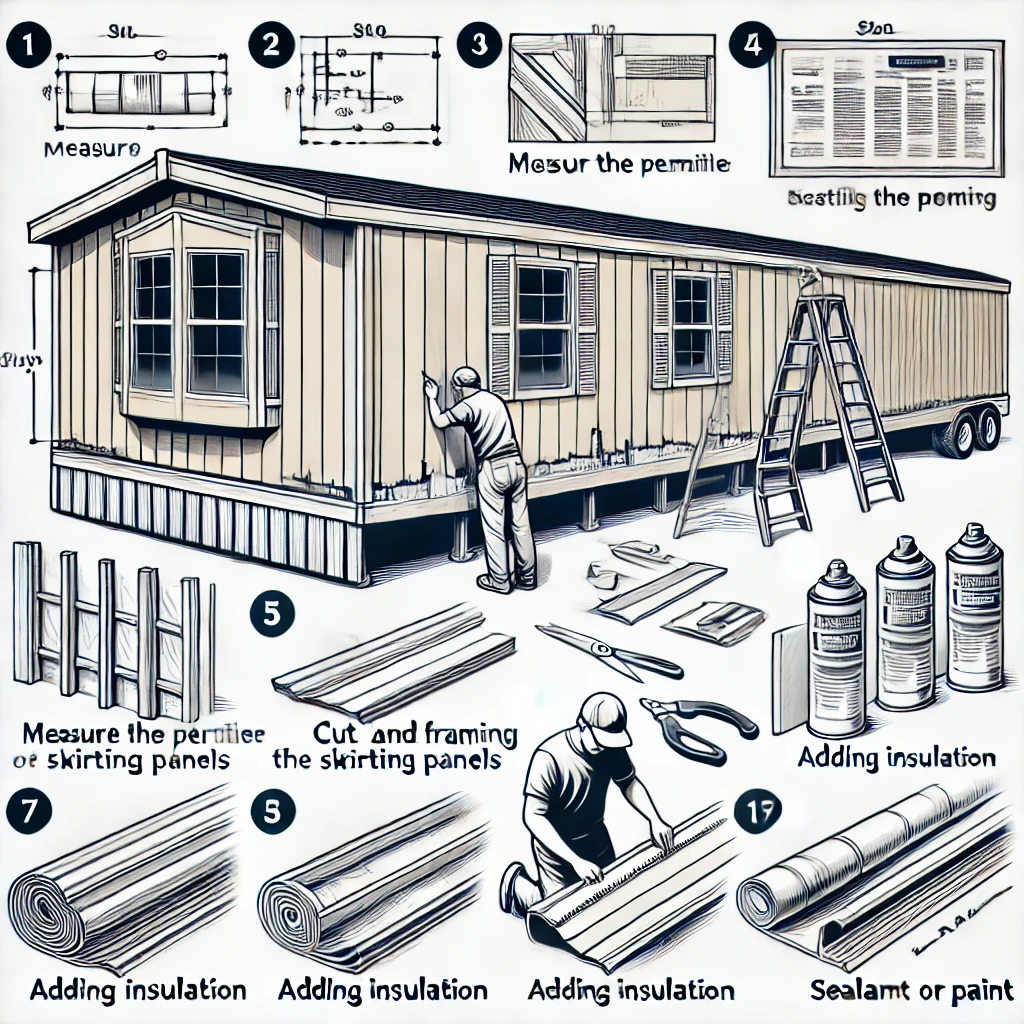

Step-by-Step Installation Guide

1. Measure and Prepare

✅ Start by measuring the perimeter of your mobile home. This will help determine how much skirting material you need.

✅ If your home sits unevenly, measure varying heights to ensure proper coverage.

✅ Mark and note any necessary adjustments based on ground-level differences.

2. Choose Your Skirting Material

Select a skirting material that fits your needs and budget:

✅ Plywood: Provides solid coverage and can be painted or stained.

✅ Lattice Panels: Offer ventilation and a decorative look.

✅ Vinyl Skirting: A budget-friendly, low-maintenance option.

✅ Metal Skirting: Durable and weather-resistant.

3. Frame the Area

✅ Construct a frame using treated lumber or galvanized metal to support the skirting panels.

✅ Cut the framing material to size and attach it to the bottom of the mobile home using screws or nails.

✅ Ensure the frame is level and securely fastened to provide a stable foundation.

4. Cut and Attach the Skirting Panels

✅ Measure and cut the skirting panels to fit between the frame, leaving a small gap at the top for ventilation.

✅ Use a circular saw or hand saw for precise cuts.

✅ Secure the panels firmly to the frame using screws or nails.

✅ Check that all panels are properly aligned and level.

5. Optional: Add Insulation

✅ If you want better energy efficiency, consider adding insulation behind the skirting.

✅ Cut the insulation to size and place it between the skirting panels and the mobile home.

✅ Secure it properly to prevent movement or gaps.

6. Finishing Touches

✅ Apply paint or sealant to protect the skirting from weather damage.

✅ Use an outdoor-grade stain or sealant to ensure durability.

✅ Consider adding decorative trim for a polished look.

7. Maintenance

✅ Regularly inspect the skirting for damage or wear.

✅ Repair any loose or damaged panels immediately.

✅ Keep the area clean to prevent debris buildup.

Benefits of Mobile Home Skirting

✅ Energy Efficiency: Helps insulate your home, reducing heating and cooling costs.

✅ Pest Control: Prevents rodents and critters from nesting under your home.

✅ Curb Appeal: Enhances the home’s appearance by hiding structural components.

✅ Moisture Protection: Reduces exposure to damp conditions, preventing mold and rot.

✅ Compliance with Regulations: Many areas require skirting to meet building codes.

The Cheapest Way to Skirt a Mobile Home

If you’re on a budget but still want the benefits of skirting, there are several affordable options to consider. The key is to choose materials that provide durability, protection, and insulation while keeping costs low. From vinyl and plywood to lattice panels and metal sheets, you can find a skirting solution that fits your budget without compromising quality. Below are some of the most cost-effective skirting options and their pros and cons.

✅ Vinyl Skirting: Cost-effective, lightweight, and easy to install.

✅ Metal Skirting: Strong, weather-resistant, and long-lasting.

✅ Plywood or OSB Panels: Budget-friendly and customizable.

✅ Lattice Panels: Provides airflow and is easy to set up.

✅ Fabric Skirting: Temporary and inexpensive alternative.

✅ Concrete or Brick Skirting: More durable but requires additional labor.

Best Amazon Picks for Your Skirting Project

Here are some recommended Amazon products to help with your DIY skirting installation:

- Treated Plywood Panels – Durable and easy to customize.

- Vinyl Skirting Kit – Affordable and maintenance-free.

- Galvanized Metal Skirting – Sturdy and weather-resistant.

- Heavy-Duty Drill – Essential for securing panels.

- Outdoor Sealant – Protects against moisture and damage.

(Note: Check Amazon for the latest product availability and pricing.)

Mobile Home Skirting Installation

Professional installers can deliver excellent service to the client that will last the entire day. Professional experts also provide insight. They can offer advice on what’s most appropriate in a particular situation. Depending on your situation, you can find skirting that suits you best.

A professional handles the stress and detail of installing the equipment.