What is RTD Plywood

RTD plywood, short for Reinforced Thermosetting Resin Bonded Plywood, significantly advances engineered wood products. It’s a versatile material widely used in various construction applications due to its exceptional strength, durability, and resistance to moisture and temperature fluctuations.

RTD vs CDX Plywood

Compared to CDX plywood, a common type known generally for its lower grade and suitability for rough construction work, RTD plywood offers superior performance and quality.

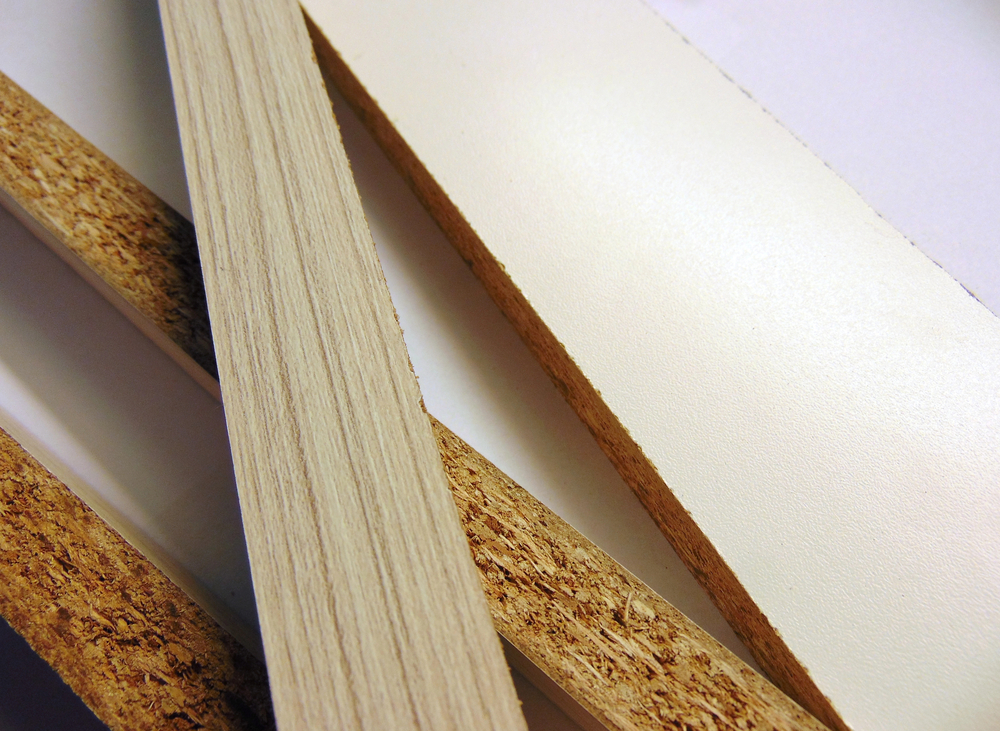

While both types are constructed with layers of wood veneers, the key difference lies in the bonding process and the added reinforcement.

RTD plywood is specifically engineered to withstand harsh environmental conditions, making it an ideal choice for exterior applications where exposure to moisture, heat, and other elements is a concern.

Its construction involves advanced bonding techniques that ensure glue between each layer is securely fused, creating a strong and stable panel that can withstand the rigors of outdoor use.

Manufacturing Process of RTD Plywood

The manufacturing process involves several crucial steps to ensure its structural integrity and high-quality performance. One key aspect is the bonding process, where thermosetting resin reinforces and bonds the plywood layers.

High-quality wood veneers are carefully selected in the initial stages based on their thickness, grain orientation, and overall quality. These veneers are stacked together, each layer positioned perpendicular to the adjacent one to enhance strength and stability.

Next, the bonding process begins, wherein a thermosetting resin is applied to the exposed veneer layers. This resin is a bonding agent, effectively gluing the layers together under heat and pressure. The result is a solid panel with enhanced structural integrity and resistance to delamination.

Quality control measures are implemented throughout manufacturing to ensure that each panel meets rigorous standards. This includes testing for moisture resistance, dimensional stability, and overall strength to ensure the highest quality final product.

Applications and Uses of RTD Plywood

RTD plywood finds a wide range of applications across various industries thanks to its durability, versatility, appearance, and resistance to moisture and temperature. Some of the common uses of RTD plywood include:

- Exterior Panels: It is widely used in constructing exterior walls, siding, and facades due to its ability to withstand exposure to moisture, heat, and other environmental factors. Its superior moisture resistance makes it an ideal choice for outdoor applications where traditional plywood may be prone to warping or rotting.

- Roof Sheathing: RTD plywood is commonly used as roof sheathing material in residential and commercial construction projects. Its strong and durable nature protects against inclement weather, ensuring the roof’s structural integrity over the long term.

- Subflooring and Walls: RTD plywood is also utilized in subflooring and wall construction, where stability and durability are paramount. Its ability to withstand moisture and temperature fluctuations makes it suitable for use in areas prone to high humidity or temperature changes.

- Cabinets and Furniture: These are increasingly used in manufacturing cabinets, furniture, and other interior applications. Its smooth surface, dimensional stability, and strength make it an excellent choice for creating high-quality furniture pieces built to last.

Advantages of RTD Plywood

RTD plywood offers several advantages over traditional and other building materials, making it a preferred choice for many construction projects. Some of the key advantages include:

- Complete Waterproofing: RTD plywood is engineered to be completely waterproof, making it suitable for outdoor use and areas where exposure to moisture is a concern. Its superior moisture resistance helps prevent warping, swelling, and rotting, ensuring the structure’s longevity.

- Resistance to Delamination: Unlike traditional plywood, which may be prone to delamination over time, it is designed to resist separation between layers. This helps minimize the risk of defects and construction delays, ensuring that the project stays on schedule and within budget.

- Suitable for Short-Term and Long-Term Projects: Whether a short-term construction project or a long-term investment, RTD plywood offers the versatility and durability needed to meet various project requirements. Its ability to withstand moisture, temperature fluctuations, and other environmental factors makes it suitable for various applications.

Considerations and Conclusion

Several factors should be considered when selecting RTD plywood for a construction project to ensure optimal performance and longevity.

These factors include:

- Thickness, Grade, and Price: RTD plywood has various thicknesses and grades, each suited to different applications and budgets. Choosing the right thickness and grade is essential based on the project’s specific requirements and the plywood’s intended use.

- Comparing RTD Plywood with Other Materials: While RTD plywood offers many advantages, comparing it with other building materials is essential to determine the best option for your project. Factors such as cost, availability, and specific performance requirements should be considered when making comparisons.

In conclusion, RTD plywood stands out as a reliable and versatile building material with superior strength, durability, and resistance to moisture and temperature. Its advanced manufacturing process and numerous advantages make it an ideal choice for various construction applications. Whether used for exterior panels, roof sheathing, subflooring, or furniture, it provides the performance and reliability needed to ensure the success of any construction project.