In search of good hardwood plywood? Ash may be the ideal choice. This guide provides a complete overview of ash plywood’s properties and uses, along with detailed information about the most popular types of ash plywood on the market.

Introduction to Ash Plywood

Overview of Ash Plywood

- High-quality technical panel for industrial, engineering, and decorative applications, including furniture and shopfitting installations.

- It’s commonly used where ash’s technical characteristics are desirable, such as in sports equipment and decorative furniture.

- Used in engineering applications where dimensional stability is important.

Benefits and Characteristics

- Durable, lightweight, flexible, and stain-resistant, making it popular in mid-century furniture and design.

- The heartwood is light brown, with darker shades also present, while the sapwood can be very wide and tends to be beige or light brown.

- Known for its strength and durability, making it an excellent choice for heavy-duty applications.

Ash Plywood Types

Rotary Ash Throughout Plywood

- Used for applications requiring strong, resilient, and decorative plywood, such as toy and model making, interior decoration, and sports equipment manufacturing.

- Faced with 2.5mm veneers and a core of 2.5mm thickness rotary peeled ash veneers throughout.

- Some thicknesses include 1.7mm veneers in the core to achieve the required finished thickness.

Ash Faced Plywood

- Used to minimize end-grain visibility and often used as ash drawerside plywood for making drawer sides and ash plywood skirtings.

- Core veneer directly under the face is bonded at right angles to all other layers, offering increased stability and reduced splitting.

- This layup increases bending strength and stiffness in the direction of the grain, reducing torn fibers and giving a cleaner edge finish.

Quality and Grading

Factors Affecting Quality

- The quality is affected by the quality of the ash wood used, including the heartwood and sapwood.

- The manufacturing process and core quality also impact the overall quality of the plywood.

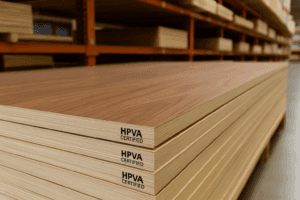

Grading Standards

- Graded based on the quality of the face and core veneers.

- The grading standards take into account factors such as knot size, knot frequency, and veneer quality.

Core Quality

- All veneers used in ash throughout plywood are closed, without open defects.

- Ash win plywood can be supplied as ‘closed’ or ‘standard’ cores, allowing some small knotholes and open defects in the core of other woods.

- Stock and Availability

Thickness Options

- Ash plywood is available in various thicknesses, including 1/4” and 3/4” thickness.

- The thickness options make it suitable for a wide range of applications, from furniture making to construction projects.

Ash Plywood Properties

Ash trees used for plywood offer beautiful wood with plenty of strength, shock resistance, and density. The grain is often smooth and tight, making this some of the best plywood for decorative purposes. As for color, ash plywood is typically light brown throughout the heartwood portion, with a pale beige to light brown color through sapwood regions. Depending on individual pieces as well as grade, it’s sometimes possible to obtain ash hardwood plywood without clear demarcation lines that show the difference between heartwood and sapwood.