Cutting plywood without splintering is a skill every woodworker should master. It might look easy at first, but even one bad cut can leave your material shredded along the edges. Whether you’re working on furniture, cabinets, or wall paneling, splinter-free plywood cuts make your projects cleaner, faster, and more professional.

In this updated 2025 guide, I’ll show you how to cut plywood cleanly using the best tools, blades, and techniques—plus real-world tips I’ve learned over the years of experience.

🪚 Why Cutting Plywood Without Splintering Can Be Tricky

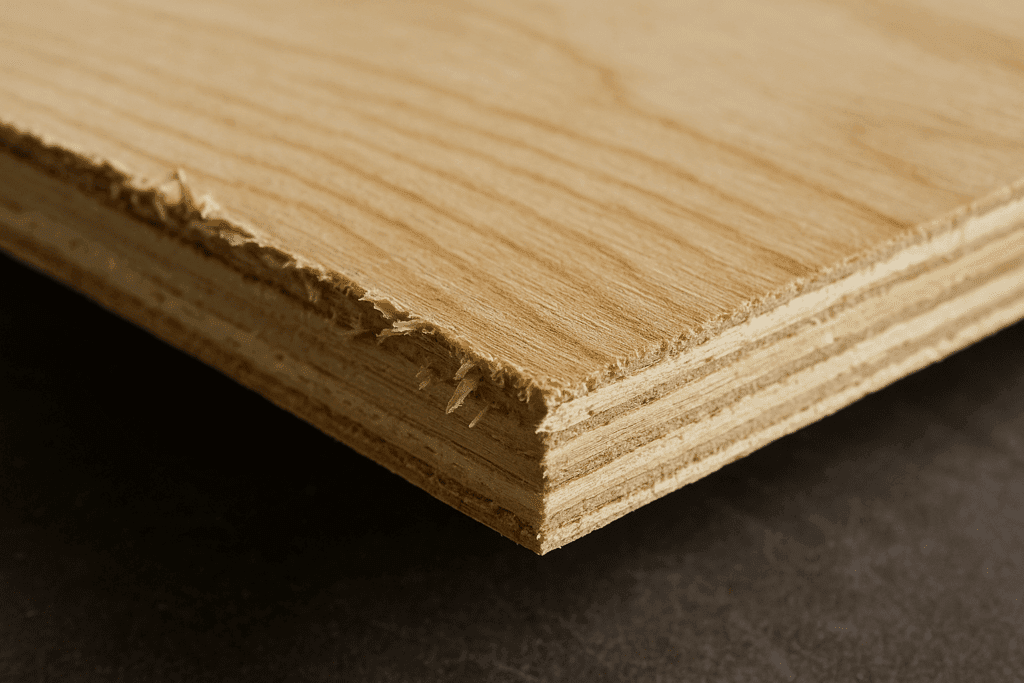

Plywood is made up of thin veneer layers glued together in alternating grain directions. This cross-laminated structure gives plywood strength, but also increases the risk of splintering. Most tear-out occurs where the blade exits the material.

Common causes of splintering plywood:

- Using dull or aggressive-tooth blades

- Cutting too fast or too slow

- No scoring or taping the cut line

- Unsupported edges beneath the cut

🧱 Plywood Grades and How They Affect Cutting Results

Choosing the right plywood type is just as important as using the right tools. Some grades splinter more than others.

| Grade | Description | Splinter Risk |

|---|---|---|

| A-C | Sanded front, utility back | Low on A side |

| B-C | Repaired face, utility back | Moderate |

| CDX | Rough sheathing use | High |

| Baltic Birch | All hardwood veneers | Very Low |

For exposed edges, always choose furniture-grade or Baltic birch plywood.

🧰 Best Tools for Cutting Plywood Without Splintering

Clean cuts start with the right tool for the job:

🔨 Circular Saw + Guide Rail

Affordable and effective with the right setup.

- Use a 60-tooth or higher fine-finish blade

- Clamp a straightedge or use a guide system

- Cut face-down (so splinters occur on the bottom)

🪚 Track Saw

Professional-grade precision.

- Built-in splinter guard prevents tear-out

- Ideal for breaking down full 4×8 sheets

🧲 Table Saw

Great for repeatable cuts if you have space.

- Use a zero-clearance insert

- Feed plywood slowly for smooth results

🪜 Jigsaw (For Cutouts)

Use a down-cut blade to protect the top veneer.

- Perfect for sink cutouts, curves, and notches

🔪 Best Blades for Splinter-Free Plywood Cuts

| Blade Type | Tool | Teeth | Best Use |

| Fine Finish | Circular Saw | 60T+ | Long cuts, furniture projects |

| Triple Chip Grind | Table Saw | 80–100T | Cabinet work, veneered panels |

| Down-Cut | Jigsaw | 10–20 TPI | Clean top veneer cuts |

Avoid coarse framing blades—they’re designed to rip, not finish.

✂️ Pro Techniques for Cutting Plywood Without Splintering

You can get crisp edges even with basic tools using these pro-level tactics:

- Score the cut line with a utility knife before sawing

- Tape the cut using painter’s tape to prevent lifting fibers

- Support the sheet fully with foam board or scrap plywood

- Use a backer board for handheld cuts to avoid bottom tear-out

- Make shallow passes first for final full-depth cuts

🔧 Solo Workshop Setup: Cutting 4×8 Plywood Alone

Working solo? Here’s how I handle large panels:

- Place 2″ foam insulation on two sawhorses

- Lay plywood face down across the foam

- Clamp a guide rail where needed

- Score the line, then cut slowly with a fine blade

🧪 Real Example: Plywood Cabinet Build

For a recent custom-built-in, I needed 10 flawless panels. I used prefinished maple plywood, taped and scored each line, and cut with a Makita track saw using a 55T blade. No splinters—just clean edges ready for edge banding.

Labeling each piece with masking tape kept everything organized during assembly.

🧼 Finishing Your Plywood Edges

Even perfect cuts sometimes need polishing:

- Sand with 220-grit for paint-ready edges

- Edge Banding: Use iron-on edge tape for a furniture-grade finish

- Router the edge for decorative profiles

- Add solid wood strips if staining the surface

💬 Pro Builder Advice on Plywood Cutting

“Scoring the cut line saves me so much sanding. It’s now my non-negotiable step.” – Brian, cabinet builder

“I used to think I needed a $400 saw. Turns out a $60 saw and a $30 blade work magic.” – Cynthia, DIYer

“Supporting both sides of the plywood makes a world of difference. No more chipping.” – Raul, workshop instructor

📋 Final Checklist for Cutting Plywood Without Splintering

- Use a 60T+ fine-finish blade

- Tape and score the cut line

- Cut face-down (circular saw) or face-up (table/jigsaw)

- Use a guide rail or clamped straightedge

- Support the sheet fully with foam or MDF

- Go slow—let the saw do the work

- Label each panel after cutting