Wood spools, from those used for sewing to those used for electrical transmission lines, have been repurposed for various uses since they first started appearing. Whether we’re talking about the simple wood spools used for sewing thread or the larger ones used for rope on sailing ships, people always seemed to find a plethora of uses for these structures. But in recent times, the only spools still made of wood are those for electrical transmission lines, telephone wires, and cable TV.

These large wood spools come in various sizes and are commonly used for making furniture, especially tables. But tables aren’t the only thing you can make out of them. People have used these to make portable bars, fishing rod holders, playground equipment, cat towers, chicken coops, and wine racks. The only limits to what can be made out of them are your capacity for creativity and woodworking expertise.

More than anything, though, wood cable spools are used for making furniture, especially tables. The spool itself almost makes a table without any further modification. Chairs are a bit more trouble but by no means a complex undertaking to create. Small wooden cable spools can also be used as stools by adding a padded top.

So, Where Can You Find the Spools?

The spools we’re talking about are, like that, other excellent materials, pallets, and leftovers from other construction and industrial uses. Mostly, they are items used for shipping cables that electric companies use. However, some lines that other utility providers use may also come on smaller wood spools. So, as a general rule of thumb, the starting point for all wood cable spool projects is your local electric company.

Not all electric companies sell their leftover spools; some recycle them to the manufacturers they buy their cable from. Others only sell them in bulk, not wanting customers to have to deal with the extra paperwork of the sale. So you might have to do a bit of looking around to find spools that you can buy.

Even so, a good starting point is to check with your local electric company and see if they have spools for sale. Even if they don’t, if you happen to stumble across one of their crew’s stringing lines, stop and talk to them. Ask them questions about what they do with their spools when they’re done with them, and if you can, bring along a box of donuts to share. Somehow, donuts make conversations smoother and might get you the answers you want. Also, the guys might show you their appreciation by forgetting and leaving a spool behind when they leave. Just be ready to pick it up before someone steals it.

Another pair of good sources for information on these spools are Craig’s List and the Facebook Marketplace. I’ve found spools listed in both these places, generally ranging from $25 to $50, depending on the size, condition, and seller.

Finally, look for places that sell second-hand junk, primarily commercial and industrial junk, rather than the more basic type of things that people would have in their homes. If you can find one of these products at these places, they’ll most likely have spools and other exciting things, like shelving, racks, and stands, that might be useful in your workshop or business.

One warning I’d like to make is that many smaller spools, such as those used for cable TV or video and wiring, might have wood ends but a cardboard core. So don’t assume anything when you hear someone has spools available for purchase. Make sure you know precisely what the spools are. The ones with cardboard cores are still usable, but those spools may also have plywood ends rather than ends made of slats.

What About Making Your Own?

If you have trouble finding a wood cable spool, you might consider making your spool. This is possible but relatively tricky. The big problem is connecting the ends to the slats that make up the center of the spool. In commercially sold, manufactured spools, these are inset into a slot routed into the inner side of the spool’s ends. Then, all thread is run through from one side to the other to hold the whole thing together.

Ends are pretty easy to make, so if you want to learn how to make a project item that requires nothing more than spool ends, such as a patio bench, you can easily make your fake ends, and nobody will be the wiser. For this bench, the wood spool ends would become the bar ends, with arms, and the bench seat and back would be made of pallet wood.

So to make those ends, all you need to do is put together two layers of lumber, 1″ x 6″ x or 1″ x 8″ s, whichever you can get a reasonable price on. You’ll want to use an inexpensive grade of pine boards, such as No. 2. Most building materials centers stock this, which is the lowest price in 1″ dimensional boards.

Determine the diameter of your tabletop and cut off your boards to just a bit longer. Lay enough boards side by side to make up that dimension and clamp them together. Then, start laying pieces on top of them, perpendicular to the first layer, gluing and nailing the new layer to the existing layer of boards, and being sure to put nails into each board. Continue adding additional boards to either side of the first one, butting up tight against each other until the entire width of the first layer is covered.

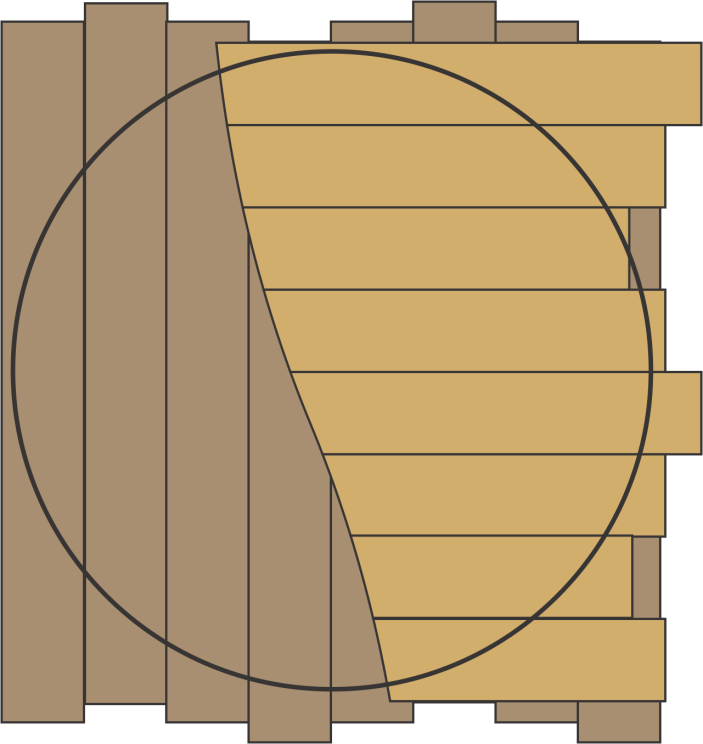

Wood spool – Homemade end

Allow time for the glue to dry, and then remove the clamps. Mark a circle with a string compass on the surface and cut it out with a jigsaw. Voila! Instant spool end, and you can make it any size you need. Add a center hole and holes for the all-thread rods, which generally hold the spool together.

You’ll probably want to distress this spool end to make it look like it has been used. A few chips in the edges and some fake wormholes made by nail worms should do the trick. Even a little used motor oil rubbed haphazardly along the edges to stain the wood dark and make it look like the spool has been in a machine will help the overall appearance.

Making Tables Out of Wood Spools

Tables are the most common and easiest to make from large wood cable spools. You may be tempted to upend your spool on one end and call it good, but if you do that, you’ll find that you can’t pull a chair up under that table. If that doesn’t matter, then that’s fine, but the only time I’ve seen that it isn’t a problem is when a small spool is used as an end table.

To use a large spool as a table you’re going to sit on, you’re going to want to cut down the diameter of the side sitting on the floor. To do so, upend the spool onto the side you want to use as the top. Then, scribe a line six to eight inches from the spool’s edge.

This is your cut line. Cut it off with a jigsaw. Be careful, as the cutoff pieces probably won’t fall free, except in large chunks, which will tend to be heavy if they land on your toes.

Once you’ve cut the foot side down, sand the edge with a power sander to smooth it out. You may also want to route what will be the top edge with a round-over bit to eliminate the risk of splinters. Please clean up the bottom edge, although it doesn’t need to be rounded.

Before flipping the spool back over, you will want to attach something to the bottom side of the base to space it off the floor, either rubber or felt pads. This will help prevent scratching the floor or snagging on the carpeting.

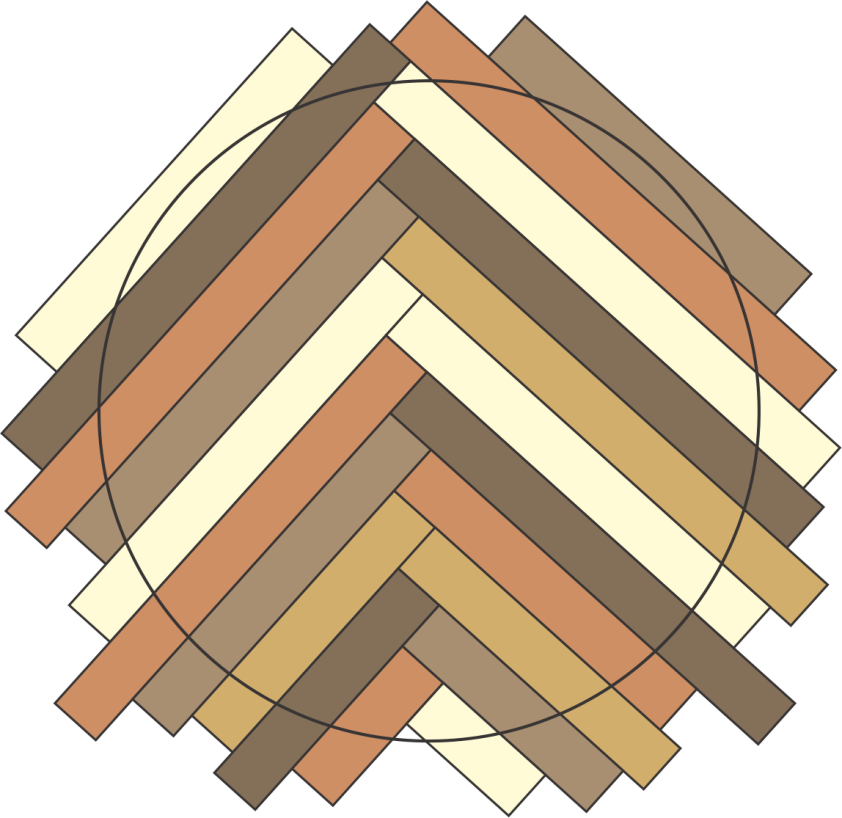

You can either leave the top side of your spool natural, the way you received it, or cover it with something, depending on your preferences. Covering the surface with pallet wood is an excellent option, making a herringbone design. This is extremely easy and will make your table look more unique.

Wood spool – Herringbone

Once the boards are glued and nailed in place, all you have to do is cut around the edge of the existing spool to make the herringbone design match the existing wood. Then, you’ll probably need to smooth the edge out with a round-over bit to eliminate splintering caused by cutting the pallet wood.

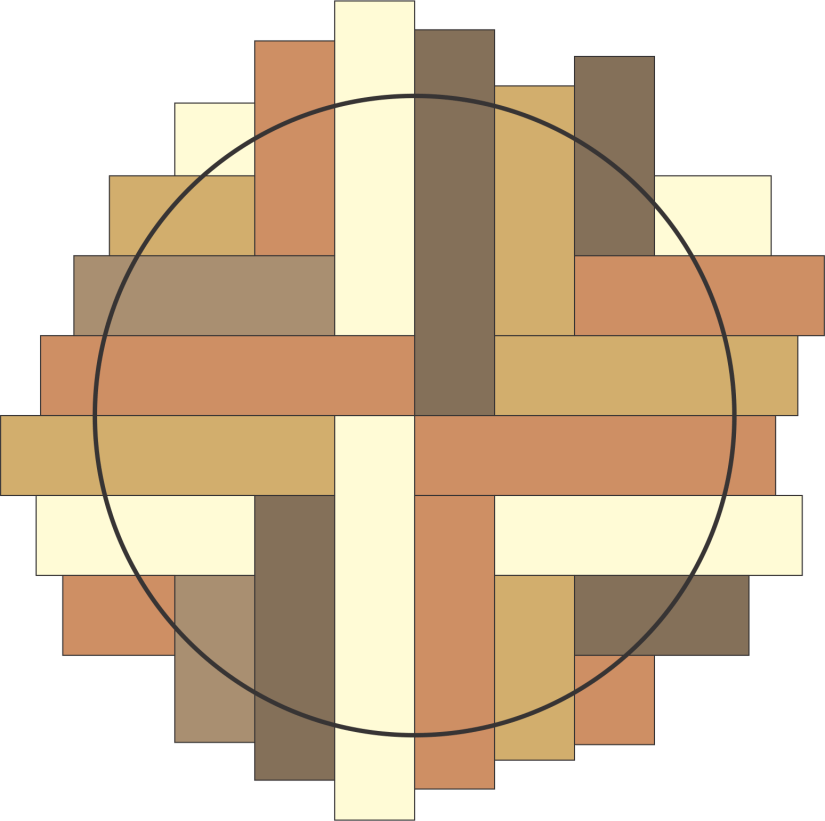

A modification of this basic herringbone design takes the same idea and starts from the center, working outwards to all four compass points, as shown in the diagram below. While this requires more cuts and some care in laying out, it’s not much more complicated than the basic herringbone design shown above.

Wood spool – Double Herringbone

While the design of the top of the table is where most people concentrate, you might want to consider what you want to do with the center of the spool, which becomes the column or single leg of your table. Here are a few ideas you might want to review and consider:

- Wrapping it with sisal or hemp rope, giving it a nautical flair

- Cutting out a couple of boards and making a door out of them so that you can use it as a storage cabinet

- Cut out the boards and forget about the door; just put shelves inside

- Drilling 3″ diameter holes to use it as a wine rack. Be careful with this idea, though, as you’ll need something inside the spool’s center to keep the wine bottles from falling inside the spool.

Finishing the Spool

As with any woodworking project, anything you make from a wood spool isn’t finished until you apply some finish. You could leave the wood bare, especially if you plan to use it outdoors. But without any finish applied, the wood will likely become more damaged.

Paint is usually out for most people, too, as it hides the rustic beauty of the spool, the whole purpose of using it in the first place. That leaves us with varnish, the usual finish when we want to bring out the natural beauty of wood. Before applying that perfect varnish, you will probably want to do some prep work on the spool.

Before any sanding or finishing, you want to be sure the wood is dry and hasn’t soaked up water from the rain or cleaning it. The wood of the spool will be naturally very dry, even if it was stored outdoors unless it rained within the previous few days. In that case, it will probably soak up water like a sponge. You’ll need to give it a few days of the weather and sit in the sun to dry out.

Sand the entire thing with 80-grit sandpaper and a vibratory sander. If there are markings or details on the spool that you want to preserve, avoid sanding those areas. This level of sanding aims to eliminate sharp points, splinters, and anything else that might make the table uncomfortable to use.

I thought you would stop with the 80-grit sanding, although you could go finer. But this is a rustic piece, so it’s not like you want a fine finish on it. If you are, you might want to forego the sanding and go for one of those poured-on 50-coat-in-one finishes. But if not, stick with me to step two.

Some people like staining their spools rather than leaving them naturally. If so, that’s your choice. Just realize that the spool will probably soak up a lot of stains. Be extremely careful around the core if you wrap the core with rope. Both sisal and hemp will soak up stains, discoloring them.

The next thing to do is apply sanding sealer. Expect the wood to soak up a lot of it, as the sealer will seal the pores in the wood. However, the sealer will seal those pores better than varnish, saving you in the long run. Allow the sanding sealer to dry, then apply two coats of varnish, sanding lightly with 220 grit sandpaper between them.